Kumar Kobra Khukuri

A Khukuri (alternately spelled kukri, khukri, kukhri, cookri or kookeri) is the traditional knife of the Himalayan Kingdom of Nepal. It is also the weapon and general-purpose tool of choice of the Gurkhas, the world-renowned legendary fighters from the foothills of the Himalayas, who have served the British Army with great distinction since the early 1800s and who have fought in decisive battles in both World Wars on battlefields around the globe, as well as in the Korean War and in Afghanistan.

Dracula: a victim of the khukuri

The khukuri is truly an ancient weapon; when the first Japanese katana was brand new, the khukuri was already at least a thousand years old. The khukuri came to be known to the Western world when the British East India Company came into conflict with the growing Gorkha Kingdom, culminating in the Gurkha War of 1814–1816 (Anglo–Nepalese War). The weapon gained literary attention in the popular 1897 novel Dracula written by Irish author Bram Stoker. Despite the popular image of Dracula having a stake driven through his heart at the conclusion of a climactic battle between Dracula’s bodyguards and the book’s heroes, Jonathan Harker and Quincey Morris, protagonist Mina Harker’s narrative describes the vampire’s throat being sliced through by Harker’s khukuri and his heart pierced by Morris’s Bowie knife.

In real life, Gurkhas (Gorkhas) continue to serve as elite soldiers in the 3,640-man Royal Gurkha Brigade of the British Army, as well as in the Indian Army and the Royal Nepalese Army. The Gurkhas display such loyalty, endurance, tenacity and incredible bravery that sometimes just the sound of their battle cry, Ayo Gorkhali! (Nepali for “Here come the Gorkhas!”), has caused enemy soldiers to flee in terror.

The weapon/tool is somewhat of an oddball here in the United States (although a small minority of supporters are quite vocal in their praise), but perhaps both the military and civilian markets should take a closer look at the khukuri for potential uses in our seemingly more violent and uncertain world. In terms of utility, the khukuri is more of a cross between a Bowie knife and a Native American tomahawk, and would seem to be a natural weapon for Americans given the prominence of our history with these two other weapons. Not only is it a slicing weapon; it is a smashing weapon as well.

Indeed, the khukuri is a superior blade, both as a combat weapon and as a tool. The unique shape of the khukuri makes it excellent both for chopping wood and for hacking through dense jungles and forests – serving as a combination of an axe and a machete, or anything else requiring a good knife. The forward curve of the blade makes this an excellent tool for chopping when it comes to procuring fire wood. The energy of the chop is centered at the inner apex of the curvature of the blade and focuses all the energy to that point for a penetrating chop. This makes it a particularly ideal item for the outdoorsman, hunter, hiker or explorer, or anyone who needs a rugged multi-functional blade. Standard-sized khukuris are between 12 inches and 30 inches overall.

Khukuris of five hundred years or more hang from the walls of Nepal’s National Museum, dating back to the Malla period. Some have suggested that khukuri design is linked to the ancient Greek kopis knife and that the form was introduced into the Indian subcontinent by Alexander’s Macedonian army, which invaded north-west India in the 4th-century B.C. If so, then the khukuri is perhaps also linked to the ancient Egyptian kopesh blade, likely the model for the Greek kopis, as well as to the Anglo-Saxon and Scandinavian seax. However, it is also possible that the khukuri is simply a design native to the foothills of the Himalayas, perhaps originating from an agricultural tool.

- Kumar Kobra

The Kumar Kobra is known by some as the lightest, quickest khukuri in the world. It most-often is made in three lengths (as measured in a straight line from the tip of the blade to the end of the handle, which is sometimes made of horn and also of various types of wood.) The various length models weigh between about 18 ounces and 2 pounds, depending on the kami (knife-smith) who made it. In any length, this type of khukuri is very suitable for martial artists and for self-defense. Like other khukuris, the blade is propelled by momentum rather than “pushed” at its target like a fencer’s foil (which might endanger the fingers). Once comprehended by the weapon’s user, the concept can be adapted to any angle of attack.

Kumar Bishwakarma in 1999

Kumar Bishwakarma, designer and maker of this 20-inch Kobra, is from the Dharan area of Nepal (110 miles ESE of Katmandu.) Dharan, in the Sunsari District, is situated on the foothills of the Mahabharat Range in the north with its southern tip touching the edge of the Terai region. It serves as a trading post between the hilly region and the plains of Terai region and was once the location of a recruitment center for the Brigade of Gurkhas. In this first photo, taken about 1999, he was a young man, who was already producing very good unique khukuris.

Kumar Bishwakarma in 2015

2015 found Kumar living with his second, younger wife; they have three children and the oldest boy will attend college in a year or so. This event will be monumental. The Nepalese caste system is complex and continues a tradition of social stratification of Nepal, even though legislation legally ended it. The system broadly borrows the classical Chaturvarnashram model consisting of four broad social classes or varna: Brahmin, Kshatriya, Vaishya and Sudra. Iron workers, which include Khukuri makers (kami) are from the lowest caste, Sudra, and at one time would have been part of the “Untouchables.” Thus, eighty percent of the kamis neither read nor write. In September 2015 Kumar was seriously hurt making a knife, when apparently the blade flipped while polishing and cut both his forehead and an electrical line that seriously shocked him.

Many of the best khukuris are made by master kamis. A master kami was born a kami in both caste and work. For as long as anyone in the family can remember, his forefathers were kamis. At perhaps age five or six, he began helping his father and grandfather in the arun, or workshop, where he learns to pull the chain on the bellows, gather charcoal for the forge and bring water for the quenching pitcher that tempers the blade. He also learns the names of tools and procedures. At around twelve years of age, he is using the hammer and does much of the pounding of heated steel that goes on in the shop. He can make a few simple farm implements by himself. Sometimes his effort produces a quality tool, sometimes not.

By the time he is 20 years old, he can fire up the shop by himself and can produce many items. He can make a decent khukuri by himself but it sometimes will not be perfect. At 30, he is called an intermediate. At around 40, depending on the person, he is just about ready for the status of master kami. His grandfather has died and his father is too old to do much work, so it is on his shoulders to take over the operation of the arun. At this stage he has made every farm tool that can be made. He will make a perfect khukuri 99% of the time. He understands steel and knows how to work it. He also has made hinges for gates and cabinets. He has made prybars and wedges in addition to sharp-edged tools.

By this time in his career, he has made sickles, scythes, axes, rakes and hatchets. He can make rings, bracelets, ear rings, pliers, tongs, awls, nails, needles, metal baskets and rivets. If you show him sketches of something you want made and give him a few verbal instructions he can produce what you want.

5160 Straight Carbon Spring Steel leaf-springs

The steel used in khukuris produced in the small forge in BirGorkha, Nepal is recycled from the 5160 Straight Carbon Spring Steel leaf-springs off of large cargo trucks preferably Mercedes or Saabs that are past their operational life. Using “recycled” leaf-spring steel means that the steel has already passed numerous vibration stresses in its original use; it is also improved as a forging medium in that it has been “work hardened” or “work strengthened,” with countless flexing and jolts in the suspension have worked out the molecular flaws and alignments, to the point that even if it not useable as a spring any longer, it is still an excellent medium for hammer and anvil. Much of the work involved in hammer-forging a blade is shaping, and then compressing the steel to eliminate “spongy” areas which would not heat treat or form properly. “Work hardened” steel goes through the process faster and easier, and makes a better blade.

- Khukuri forge at Himalayan Imports

The kamis heat the spring at the length they want and use a chisel to cut off the desired length. They can guess within a couple of ounces without weighing even though scales are available. They then start the forging process, heating and pounding, forming the blade from tip to tang (see left.) During the forging process the basic tools of the master kami are a small hammer and tongs only. Adjustments to keep the blade straight and headed in the right direction are done by the master kami himself throughout the process and this is done by the small hammer. When he determines that the blade is close enough to completion the big hammer is no longer used and he will bring the blade to as near completion as he can, using his small hammer. Then he moves to various small hand tools and file to get the blade into final shape and ready to harden. The only high tech part of this process is using an electric fan to drive the forge and later an electric grinder to get rid of hammer marks. When the blade is as close to final form as they want to get it, they harden it.

It is the heat treatment which effects certain changes in the steel, which gives one the desired end product. Inferior heat treating of even the best steel will yield an inferior khukuri. Hardness of steel is generally measured by units known as Rockwells on the so-called Rockwell “C” scale as follows: 20-25 Rc – this is the hardness found in mild steel and edge retention is poor; 30-40 Rc – some blade experts believe that this is the minimum softness that should be allowed; 40-45 Rc – this hardness level will have some spring qualities; 50-52 Rc – this rating gives a good balance between toughness (slightly soft, enough for shock tolerance) and hardness (for edge holding); 58-60 Rc – many experts feel this is the ideal hardness of differentially heat treated Chinese and Japanese swords. An edge of this hardness can cut into most materials that are comparably softer. Any rating over 60 ventures into brittle territory, although hardness does not make one blade better than the other. Harder edges are more prone to chipping, and softer blades tend to roll and dent, so there are disadvantages to both. Zone-hardened khukuris made at BirGorkha often have edges at around Rc60 with a slight fade on either side of the belly, especially on the larger blades, to Rc58. Hardness of Kobra models is 59 to 60 Rc and will shave hair off the back of your hand (which is not recommended!) However, hardness results vary, as every knife is truly hand-made.

- Khukuri water quenching

The kami does this by first heating it to proper color and then water quenching by a slow pour from a pitcher. This is the most critical stage of the process, the zone hardening. Here is where the years of experience will help the kami, who knows only too well if he misses his mark here the entire project is a loss (a master kami will have a success rate of 99%+.)

Then the kami makes the handle from a block of wood or a piece of horn or antler. When the handle is almost done, the kamis makes the bolster and butt-cap. All told, it takes up to two days to produce a single khukuri by one kami. Then the knife is polished by an apprentice. Final inspection comes last and if it passes muster, off it goes to the sarkis for a leather and wood scabbard.

This is the situation that was found in the late 1970s by Bill Martino, then a middle-aged Peace Corps volunteer, who first traveled to Nepal in that capacity. It took about two minutes off the plane at Tribhuvan Airport for Bill to realize that what Nepal needed most was some employment opportunities and a few Yankee dollars flowing in not as government handouts, but as capitalism. He finally found one of the few things the Nepalese could manufacture – and manufacture well – the khukuri, and Himalayan Imports (which should have more accurately been called Himalayan “Exports”) was born.

At first he tried to deal directly with individual kamis, but found this gave no real product line; there were also problems with scabbards and small handles, made for Nepalese, not Americans, and thus often too small. Coordination was doubly difficult as more than 15,000 kamis have been involved in the making of khukuris in Nepal in recent years. In Nepal, Bill and his Nepalese wife Yangdu – daughter of Kami Sherpa, who served in Company C, Fourth Battalion, of the Assam Rifles in the Indian Army for many years – were searching for a way to standardize their khukuri. They discovered a shop in southeast Nepal that was making khukuris for the tourist market, but the operator was capable and more than willing of making a high quality, Gurkha-grade, khukuri to Martino’s specifications, instead of tourist souvenirs.

The two men would attempt a joint venture, making a top quality khukuri (with a decent sized) handle aimed at the United States and world market. They agreed to make the best that could be made and pay the price. All of their khukuri and knives would be handmade in Nepal by true craftsmen of the kami caste; the first was sold about 1988.

The more they sold, the more Bill advertised and promoted, keeping the price of the khukuris steady. Himalayan Imports gained customers and soon many of the sales were repeat orders, as their khukuris began to attract attention. After five years of struggle they were showing a profit. However, Bill Martino wanted more; he wanted to treat his workers with respect and conduct the business within his own understanding of Dharma. For example, when the khukuri craftsmen are ready to begin work, each kami goes to the manager and requests permission to make his next knife. The men agree on a price which is paid to the kami before he begins work. If the quality of his work is poor, the kami must do the job again for no additional pay. If the quality is to the standard, which both he and the manager know it should be, another assignment is given him and he is paid again. If the quality is exceptional, the kami will receive a bonus.

In addition to the pay, Himalayan Imports provides food, money, clothes or whatever might be needed to kamis who might be having troubled times. If a kami gets sick, the company sends him to the doctor or hospital and gets medicine for him (their health insurance plan.) Bill often loaned money to kamis who might need something extra like tuition and books for children’s school, so they could climb out of the caste system. In short, he looked after the kamis as though they were his own children. When Kumar was seriously injured in 2015, Yangdu sent him medical treatment funds.

HI workshops open every day at 7:00 and close at 6:00 – seven days per week. If the kamis want to work the shop is there for them to work. If they do not want to work they do not have to. Interestingly, almost all the kamis are waiting patiently every morning for the shop to open and rarely miss a day except for perhaps a wedding or a funeral. They are very happy they are able to work and earn some of the area’s highest wages, plus unheard of employee benefits, for 150 workers associated with the BirGorkha factory, a rarity in much of Nepal.

Khukuri makers who work for Himalayan Imports, or who have worked there, include the following:

The Royal Kami Lal Bahadur Bishwakarma (“Bura”)

Kumar Bishwakarma (Sunsary district; Dharan)

Nara Bishwakarma

Raj Kumar

Bhakta Koirala (Khotang district; Dhiktel)

Dhankuta

Durba

Ganga Bahadur (Sunsary district; Dharan)

Hari

Keshar Lal Bishwakarma

Lachhu

Lok

Lokendra Shasankar (Sunsary district; Dharan)

Murali Dhar Bishwakarma

Nabin Rai

Padam

Pala

Prakash Bishwakarma

Puma

Purna Sankher Kami (Sunsary district; Dharan)

Saddhu

Samsher

Santosh

Sanu Bishwakarma

Shaila

Shankar Bishwakarma

Sher Bahadur Bishwakarma

Sgt. Khadka dai

Tej Bhahadur Gatani (Sunsary district; Dharan)

Thamar Bahadur

Tilak Bishwakarma (Diktel Bazar)

Tirtha Randham (Sunsary district; Dharan)

Vim

Yuvraj

The system of bestowing the descriptor “Master Kami” appears to be of different format than what might be done in other cultures and includes a general understanding of an individual’s high skill work, and by word of mouth. Certainly, the first four names on the above list would be in this status and many others might be as well, such as Thamar Bahadur and Purna Sankher.

Bill Martino died some ten years ago. His widow runs the import end of the business from her home in Reno, Nevada. A few years before his death, Bill made the following assessment:

“I know that Himalayan Imports is doomed to extinction. Kami, Yangdu’s dad and the owner of HI is old, I am old, our master kamis are old and when we go so will Himalayan Imports. But, it is my hope to last as long as we can and continue to do what we do the best we can.”

Having now seen, felt and used this knife, I believe that Bill Martino may have drastically under-estimated the staying power of Himalayan Imports. This particular Kobra khukuri is 20¼ inches long overall; the blade, with the curve, measures 13¼ inches in length. The width of the knife along the upper (non-cutting) edge at its thickest point is 25/64 inch (0.39”.) The weight of this example is 1 pound 13 ounces. It has the maker marking of Master Kami Kumar Bishwakarma on the blade, a six-pointed star. The handle is made of dark wood, is 5¼ inches long and is fitted with a brass end cap. The height of the blade at its primary cutting area is 1.5625 inches. It is a fighting khukuri, not a chopping khukuri that would be used to cut tree limbs. An Ang Khola, World War II Style, M-43 or Ganga Ram Special model would be the best types for this heavier work. As to prying loose boards off of their mountings, only the Chiruwa Ang Khola should really be used according to the lifetime warranty program at Himalayan Imports.

- 20-inch Ang Khola

By way of comparison, a 20-inch Ang Khola khukuri is a traditional chopping tool to remove tree limbs and even to cut tree trunks. This particular example was made by Purna Sankher Kami, also from Dharan in the Sunsary district. This is a heavy weapon, weighing 2 pounds 6 ounces, with the width of the blade on top at its thickest point being 30/64 inch (0.47”.) The length of the blade is 13¼ inches. It is fitted with a brass end-cap as well. Purna (who won the first prize in 2015 at Himalayan Imports for the best produced knife) began working for HI in October 2014. His trade mark sign is a small bull head etched on the blade near the handle.

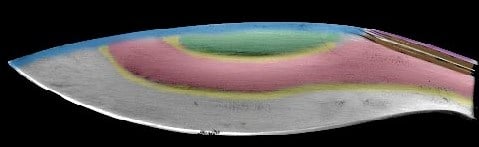

- Ang Khola Tin Chirra — three grooves

Another powerful knife is the Tin Chirra. “Tin Chirra” means three groove in Nepali. It looks just like an Ang Khola with an additional spine below the regular one, but it feels a bit heavier in the hand than the Ang Khola. The chirra, or fullers, allow a blade to have more strength than a flat bar blade of the same dimensions, with much less weight. They can be positioned along the blade to effect changes in balance, as well. Because of the complexity, a Tin Chirra can only be forged by a master kami. In the retouched photograph of the blade, the green, red and gray areas are depressed, while the ridges are highlighted yellow.

This particular model is 17½ inches long and weighs 1 pound 11 ounces. The width of the blade on top at its thickest point is 19/64 inch (0.29”.) The length of the blade is 12 15/16 inches. Thamar Bahadur was the craftsman who made this khukuri; he understudied for several years with Lal Bahadur Bishwakarma (“Bura.”) Thamar is from Gorkha, Nepal (40 miles WNW of Katmandu) and lost his house during the earthquake disaster in Nepal in 2015. He began working for Himalayan Imports in 2014.

- Thamar Bahadur

If I were still on active duty, I would be seriously examining how these khukuris could be introduced into the force – and I would be carrying one myself during training maneuvers and combat deployments in addition to my bayonet, as I did in Germany, Panama, Alaska and the Middle East with my Randall #14 – Attack, whose blade was made in Solingen, Germany. Clearly, Combat Engineers, Mechanized Infantry and Light Infantry would be prime candidates to have the sturdier khukuri, such as the Chiruwa Ang Khola, to assist in preparation of defensive positions and certain tasks in urban warfare.

There are two obvious downsides to the weapon but can be overcome. 5160 steel has 0.7 to 0.9 percent chromium, not enough to cause the metal to be corrosion resistant (to reach a more stainless steel requires >12% chromium.) Carbon steel knives, just like a rifle, need some care and attention to keep surface rust at bay. But it is tough and almost indestructible. Second, the weapon is extremely sharp and anyone using one needs to focus their attention and practice so they do not cut themselves. Gurkhas can knife fight with the weapon because of extensive training and daily use familiarity.

Give a few of these frontline units the khukuri and they will find all kinds of uses, and serve as an honest test bed for wider applications. Special Operations Command, given its separate funding stream and accelerated “off-the-shelf” acquisition ability, probably has the khukuris already – at least I would hope so. Much of the effectiveness of special operations comes from their marvelous reputation for cold-blooded efficiency combined with cerebral tactics and techniques; strapping a 20-inch razor-sharp fighting knife around the waist certainly will not “soften” that image to America’s enemies!

And for those of us back home, when your favorite ISIS punk comes calling, you can open the door, look at their knife (which, by the way, they only have confidence in using against victims who are already hog-tied) and say, “That’s not a knife,” as you draw your Kumar Kobra; “that’s a knife.”

For more information on these fantastic examples of weapons’ craftsmanship see:

Himalayan Imports

775-825-2279